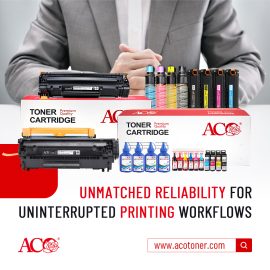

For buyers, page yield, print density, and failure rate are the three core indicators for measuring product quality. Truly excellent brands not only provide high-performance samples but also guarantee stable performance during large-volume shipments. 1. Raw Material Consistency ACO compatible toner cartridges utilize a fixed supply system. All key components, such as toner, photoconductor drum, and magnetic roller, are sourced from long-term, stable suppliers, ensuring fine toner particles, strong flowability, and uniform development, fundamentally guaranteeing print blackness and page yield. 2. Standardized Testing System ACO conducts page yield testing according to STMC international standards, strictly controlling print density and coverage. Each batch of toner cartridges undergoes multiple rounds of printing […]